Tilbury2 at the centre of a European rail network

Friday 19th June 2020

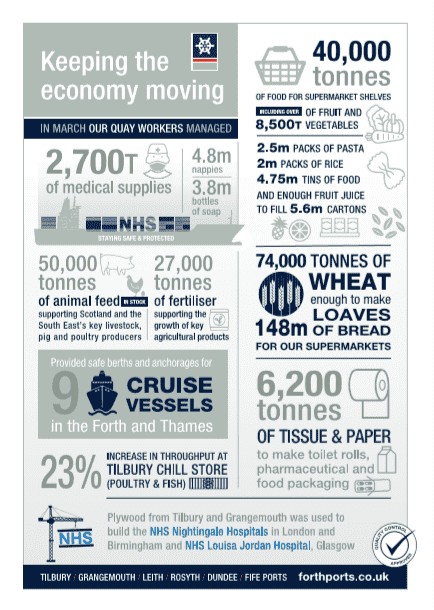

While the public gaze and political discourse has been fixed on tackling the coronavirus and preparing for Brexit, one of Britain’s major ports has launched the latest phase to its expanding footprint.

The Port of Tilbury is already the number one port in the UK across a range of cargoes – from construction materials and grain, paper to forestry products – and now it has the country’s largest unaccompanied freight ferry terminal to boot.

On 25th May, P&O’s first vessel, Wilhemine, called at the port’s new terminal on the 160-acre extension site, Tilbury2. The first call marks the rapid transformation of the former power station and the next chapter in the decade long growth of the route to-and-from Zeebrugge.

The switch to a river berth provides significant headroom for growth. P&O can bring in larger vessels, deliver faster vessel turnaround times and – most importantly – get containers and trailers onto an inland barge or the M25 and the motorway network in under an hour.

While this enhanced offering will support further growth through the Zeebrugge route and the possibility to expand into other northern European locations, it also provides a critical low carbon delivery alternative through our new rail connection.

Tens of trains a day transit across Europe to P&O’s terminal at Zeebrugge to feed their services to Britain. This pan European rail network now has a truly worthy UK leg.

In recent years through sustained investment, the Forth Ports Group has decided to resurrect its rail offering. At Tilbury, this has principally been through the creation of a dedicated bulk terminal for movements of aggregates, spoil and cullet glass, and a domestic intermodal offering to south Wales, the North West, The Midlands and Scotland supporting the retail, e-commerce, food and drink markets.

Tilbury2 provides additional capability. The site has a rail terminal capable of loading 775m length trains for both bulk and intermodal trains. This will be integral to the business model of P&O and its customers, and Tarmac, who will occupy the northern section of the site in six months’ time.

Breakdown of supply chains, unpredictable industrial relations and increasing lorry driver shortages has led many to examine the resilience of their delivery options, particularly for vital goods like food, drink and medicines. As the closest major port to Europe’s largest consumer market, Tilbury is the logical outlet in the search for reliability and speed.

As the public demand more action to abate climate change and tackle poor air quality in urban areas, rail delivery has a key role to play. Regardless of short-term depressed consumer and business demand, the legally binding framework to tackle these important matters remains.

The pursuit of net zero carbon emissions and the enshrining of air quality targets in the Environment Bill before Parliament, combined with the UK’s leading global role at the UN’s COP26 summit in Glasgow in November, will only heighten pressure on supply chains to find lower impact solutions.

Truly multi-modal delivery solutions – road, rail and barge – are key ingredients when examining the best way to deliver change throughout supply chains.

Forth Ports Group’s 25 year vision for Tilbury2 commits the port to play a central role in supporting the country’s efforts to achieve net zero through providing genuine multi-modal capability from the outset.

With one eye on the future, it’s important to mention the B word, again. In keeping with the rest of the Port of Tilbury site, the Tilbury2 terminal holds Authorised Economic Operator trusted trader status and will have access to all the border inspection facilities required for additional customs and border checks should they be required. In a sense, the terminal is “Brexit ready”, whatever the outcome of the EU-UK negotiations.

Forth Ports Group is the owner of the Port of Tilbury and seven ports on the Forth and Tay.

Tilbury2 received development consent from the secretary of state for transport in February 2019 to build Tilbury2 – a 160-acre site adjacent to the existing 930-acre site in Thurrock, on the outskirts of Greater London.

When fully operational, the £200m Tilbury2 project will comprise:

- a roll on/roll off ferry terminal for importing and exporting containers and trailers to northern Europe, in partnership with P&O Ferries

- a facility for importing, processing, manufacturing and distributing construction materials, in partnership with Tarmac

- a strategic rail terminal which can accommodate the longest freight trains of 775m

- storage areas for a variety of goods, including exported and imported cars

- trusted trader Authorised Economic Operator (AEO) accredited and will employ the latest border technology, such as number plate recognition.

The project is central to the Port of Tilbury’s £1 billion investment programme during 2012-20, which has seen it double the size of its business in the past 10 years and is projected to double the volume of cargo across the quay (from 16 million to 32 million tonnes) and increase direct employment (from 3,500 to 12,000 jobs).